Product Introduction:

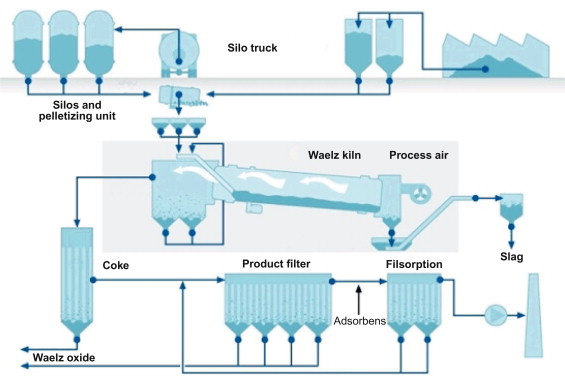

The secondary zinc oxide production technology utilizes zinc-containing waste residue (or low-grade zinc ore) and high-calorific-value, low-sulfur anthracite as raw materials. These materials are thoroughly mixed into a granular form and then subjected to a high-temperature reduction in a rotary kiln. Zinc vapor is volatilized and directly oxidized into secondary zinc oxide by the introduced air. After natural cooling through the cooling system, the product is packaged as secondary zinc oxide by a fan that draws it into a dust collection bag. The waste gas is extracted from the baghouse and treated in a desulfurization tower before being discharged into the atmosphere through a chimney. The processing system of this project mainly includes the batching workshop, granulation system, rotary kiln gasification system, kiln slag cooling system, settling chamber, flue gas surface cooler, finished product dust collection system, and desulfurization and denitrification systems.

Product Advantages:

01

The return on investment for the production line is high, and the current market price of zinc ingots is relatively high. The production of secondary zinc oxide products from zinc-containing waste residues (or low-grade zinc ore) is directly sold, and the process flow is simple.

02

This structure of the rotary kiln is simple, with strong controllability, which is beneficial for operation and maintenance.

03

Good environmental protection dust collection, using a pulse bag filter for dust removal, with an emission concentration of less than 10mg/Nm3.

04

The level of automation is high, with fewer on-site operators and high labor efficiency.

Process Flow Chart: